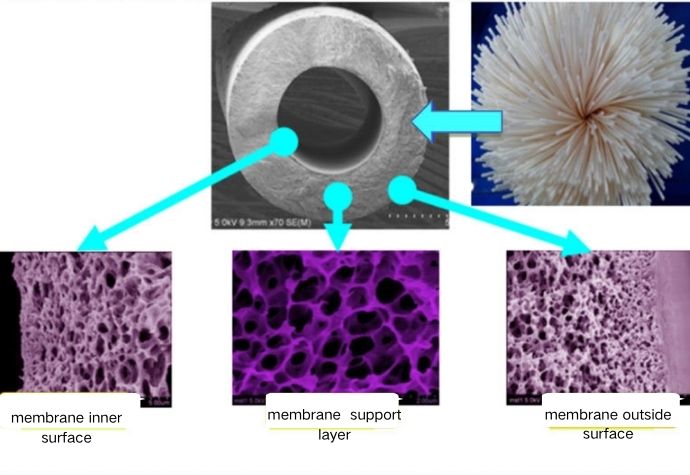

Reinforced MBR Membrane With Inner Lining

Ascend Reinforced MBR Membrane Fiber

- Innovative VNIPS Method

- Small surface pore size(0.25μm)

- High porosity

- Uniform pore distribution

- High separation accuracy

- High Fouling Resistance and High Water Production

- The high fouling-resistance PVDF hollow fiber ultrafiltration membranes produced by the company maintain a significantly higher stable flux compared to ordinary PVDF membranes.

- Permanent hydrophilic membrane surface, resistant to fouling, with high stable flux.

- Flexible Stretching Process

- High Tensile Strength (tensile strength reaches 5 MPa, ensuring long service life), without fiber breakage.

- Burst pressure nearly 0.6 MPa, separation layer is firmly bonded without delamination

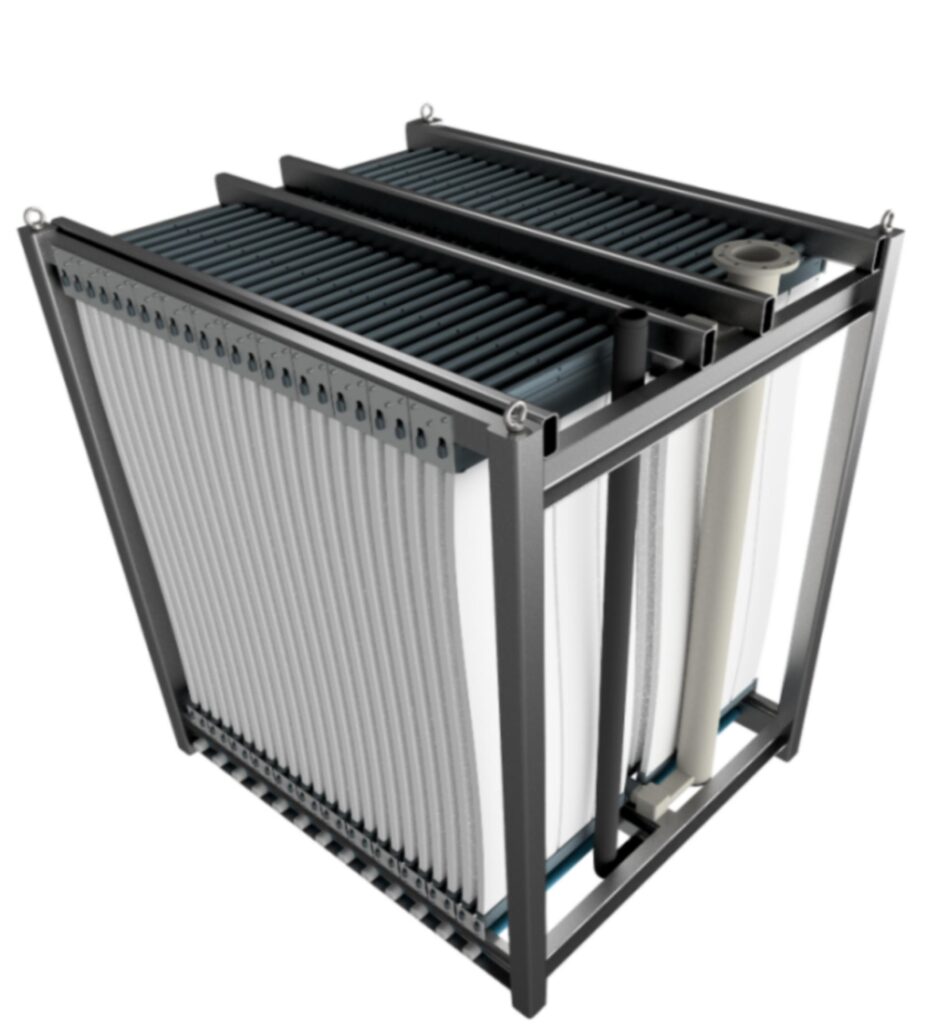

Ascend Reinforced MBR Membrane Element

Membrane fibers are used in engineering applications in the form of encapsulated membrane elements. These membrane elements are then combined to form membrane modules. Ascend MBR membrane module can accommodate up to 48 membrane elements. Currently, there are three standard area membrane elements: 10 m², 21 m², and 32 m². The membrane elements are shown in the image above.

Ascend Reinforced MBR Membrane Stacks

| MBR module Type | |

|---|---|

| Wet Membrane Length(mm) | DN100/DN80 |

| Material of MBR module | 316L/304SS |

| MBR module Dimension | 1860x2020x1500 1860x2020x2500 |

| MBR module aeration specifications | |

| The diameter of the pipe for air intake | 2x3"pipe(UPVC) |

| Maximum air temperature | 65℃ |

| Maximum instantaneous aeration capacity | 15 times the designed water yield |

| Minimum instantaneous aeration capacity | 8 times the designed water yield |

| Aerator head pressure loss (excluding hydraulic loss) | 0.05bar |

| 48 membrane elements can be reduced according to the actual situation. The membrane frame size does not change. | |

Ascend Reinforced MBR Membrane Module Features

The reinforced MBR membrane with an inner lining effectively removes suspended solids and colloids, significantly inhibiting membrane fouling.

The use of reinforced MBR membranes results in lower sludge production from wastewater, reducing subsequent sludge disposal costs

Compared to traditional wastewater treatment technologies, the reinforced MBR membrane system occupies less space, saving on investment costs

The backwashing and online chemical cleaning of the reinforced MBR membrane system are fully automated

Start Getting New Knowledge and Experience, Together!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.